This manual provides essential guidance for operating‚ maintaining‚ and troubleshooting your Mantis Rototiller. It includes step-by-step instructions‚ safety tips‚ and maintenance schedules to ensure optimal performance and longevity.

1.1 Understanding the Importance of the Manual

The Mantis Rototiller manual is a critical resource for ensuring safe‚ effective‚ and efficient operation. It provides detailed instructions for assembly‚ maintenance‚ and troubleshooting‚ helping users maximize performance and longevity. Proper understanding of the manual prevents damage to the machine and ensures user safety. By following the guidelines‚ you can avoid common issues and extend the lifespan of your tiller; The manual also serves as a troubleshooting guide‚ offering solutions to common problems. Regularly reviewing the manual helps users stay informed and confident in their ability to operate and maintain the Mantis Rototiller effectively.

Assembly and Setup of the Mantis Rototiller

The assembly process begins with unboxing and inventorying all parts. Follow the step-by-step guide for proper assembly‚ then perform initial adjustments to ensure optimal performance.

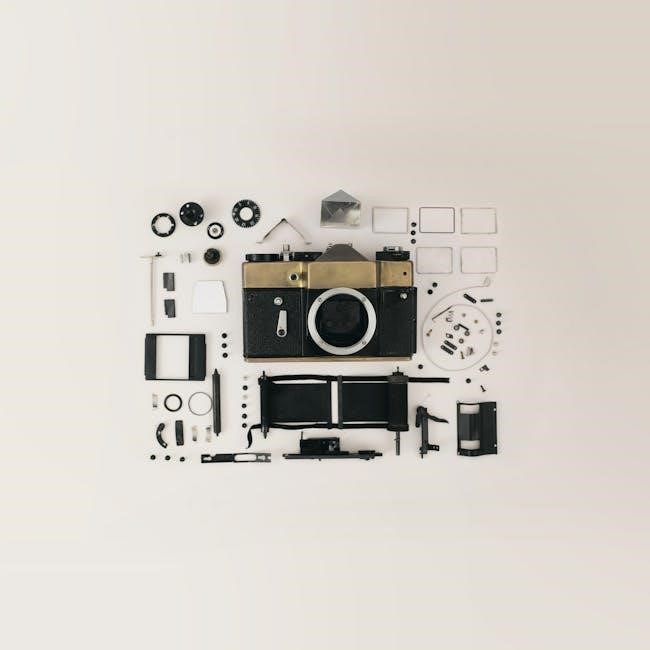

2.1 Unboxing and Inventory of Parts

Begin by carefully unboxing your Mantis Rototiller and inventorying all components. Ensure all parts‚ including tines‚ handlebars‚ and engine‚ are present and undamaged. Compare items to the manual’s list to confirm completeness. Check for any missing or damaged components and contact customer support if issues arise. Organize parts for easy access during assembly. This step ensures a smooth setup process and prevents delays. Proper inventory is crucial for successful assembly and operation of your tiller.

2.2 Step-by-Step Assembly Instructions

Begin by attaching the handlebars to the main frame using the provided bolts. Ensure they are securely tightened for stability. Next‚ install the tines by aligning them with the tine shaft and locking them in place. Connect the engine to the transmission‚ following the manual’s torque specifications. Attach the throttle and control cables‚ ensuring proper alignment and tension. Finally‚ check all connections for tightness and test the tiller’s movement. Refer to the manual for specific torque values and assembly diagrams to ensure accuracy. Proper assembly is critical for safe and effective operation.

2.3 Initial Setup and Adjustments

After assembly‚ inspect the tiller for any damaged or loose parts. Tighten all bolts and ensure proper alignment of moving components. Adjust the handlebars to a comfortable height and angle for easy operation. Set the tine depth according to the soil type and your tilling needs. Check the engine oil and fuel levels‚ filling them as required. Test the tiller on a small‚ clear area to ensure smooth operation and make any necessary adjustments. Proper setup ensures safety‚ efficiency‚ and optimal performance for your gardening tasks.

Operating the Mantis Rototiller

Start the engine‚ ensure safety precautions‚ and begin tilling with smooth‚ controlled movements. Adjust speed and depth as needed for optimal soil preparation and efficient gardening results.

3.1 Starting the Engine and Safety Precautions

Before starting‚ ensure the area is clear of debris and wear protective gear. Check the choke‚ prime the engine‚ and pull the starter cord firmly. Allow the engine to warm up briefly‚ then adjust the choke as needed. Never operate the tiller near open flames or sparks. Keep loose clothing tied back and avoid overreaching. If the engine stalls‚ turn it off and wait before restarting. Always shut off the engine when leaving the tiller unattended and ensure children are at a safe distance.

3.2 Basic Operation Techniques

Start by standing comfortably with a firm grip on the handles. Slowly advance the tiller‚ keeping it upright‚ and apply gentle to moderate pressure. For forward movement‚ squeeze the throttle and guide the machine with steady‚ controlled motions. To reverse‚ disengage the tines and carefully back up. Adjust the depth bar to regulate tilling depth based on soil hardness. Maintain consistent speed and avoid sudden jerks. For tight spaces‚ tilt the tiller slightly and maneuver carefully. Always keep the tines engaged when moving forward to ensure effective soil turnover.

3.3 Advanced Tilling and Cultivating Methods

For advanced tilling‚ use the scarifier attachment to loosen hard soil before tilling. Employ the aerator for improving soil drainage and root growth. When cultivating‚ overlap passes slightly to ensure even ground coverage. For tough sod‚ make multiple shallow passes‚ gradually increasing depth. Use the edger attachment for precise border work. Experiment with different tine angles to optimize soil turnover. For large areas‚ maintain consistent speed and overlap patterns. Adjust the tine depth and PTO settings based on soil type and task requirements. Crisscross tilling can help break up compacted clay effectively.

Maintenance and Care of the Mantis Rototiller

Regular maintenance ensures optimal performance. Check oil levels‚ clean air filters‚ and inspect tines for wear. Lubricate moving parts and store the tiller properly after use.

4.1 Routine Maintenance Checks

Regular maintenance is crucial for the longevity and efficiency of your Mantis Rototiller. Begin by inspecting the air filter and cleaning or replacing it as needed to ensure proper engine airflow. Check the oil level and top it off with the recommended grade to prevent engine damage. Inspect the tines for wear or damage‚ and sharpen or replace them as necessary. Additionally‚ lubricate all moving parts‚ such as the gearboxes and pivot points‚ to maintain smooth operation. Finally‚ examine the throttle and control cables for any signs of fraying or wear‚ ensuring they function correctly. By performing these routine checks‚ you can prevent unexpected breakdowns and keep your tiller running at peak performance.

4;2 Oil and Fuel Requirements

Proper oil and fuel maintenance is essential for your Mantis Rototiller’s performance. Use high-quality‚ 4-cycle engine oil with the recommended viscosity for your climate—thinner oils for colder temperatures and thicker for warmer conditions. Always use fresh‚ unleaded gasoline with an octane rating of 87 or higher. Avoid using old or contaminated fuel‚ as it can clog the carburetor and damage the engine. Regularly check the oil level before operation and refill as needed. Using the wrong oil or fuel can lead to engine damage or failure‚ so consult your manual for specific recommendations.

4.3 Blade and Tine Maintenance

Regular maintenance of the blades and tines is crucial for optimal performance. After each use‚ clean the blades and tines thoroughly to remove soil and debris. Sharpen the tines periodically to ensure efficient tilling. Inspect for damage or wear and replace any bent or broken parts immediately. Lubricate the moving components to prevent rust and ensure smooth operation. Store the tiller in a dry place during the off-season to protect the blades and tines from corrosion. Proper care extends the lifespan and maintains the effectiveness of your Mantis Rototiller.

Troubleshooting Common Issues

Address engine startup problems‚ tine rotation issues‚ and vibration concerns. Check fuel flow‚ spark plugs‚ and blade conditions. Refer to the manual for detailed diagnostic steps.

5.1 Engine Not Starting or Running Roughly

If the engine fails to start or runs unevenly‚ inspect the carburetor for cracks‚ especially the diaphragm‚ which may prevent proper fuel flow. Check the air filter for blockages and ensure the spark plug is clean and functioning. A cracked diaphragm requires replacement‚ as it disrupts fuel delivery. Refer to the manual for detailed repair steps or consider replacing the carburetor entirely. Regular maintenance‚ such as cleaning the air filter and spark plug‚ can prevent these issues. Always follow safety guidelines when handling small engine repairs.

5.2 Tiller Not Rotating or Moving Forward

If the tiller fails to rotate or move forward‚ check for blockages in the tines or drive system. Ensure all parts are securely attached and free from debris. A seized engine or damaged transmission could also cause this issue. Inspect the crankshaft and bearings for wear or damage. If internal components are faulty‚ refer to the manual for rebuild instructions or contact customer support. Regular lubrication of moving parts can prevent such problems. Always ensure proper assembly and maintenance to avoid operational disruptions.

5.3 Vibration or Noise Issues

Vibration or excessive noise during operation may indicate imbalanced or loose components. Check the engine for misfires or faulty spark plugs‚ as these can cause uneven operation. Inspect the tines and drive shaft for damage or misalignment‚ which can create noise. Ensure all bolts and screws are tightened securely. If issues persist‚ lubricate moving parts or replace worn components. Consult the manual for specific troubleshooting steps or contact customer support for assistance. Regular maintenance can help prevent vibration and noise problems‚ ensuring smoother operation.

Attachments and Accessories for the Mantis Rototiller

The Mantis Rototiller offers various attachments like scarifiers‚ aerators‚ and edgers to enhance functionality. These accessories expand the machine’s versatility for different gardening and landscaping tasks efficiently.

6.1 Overview of Available Attachments

The Mantis Rototiller supports a variety of attachments to enhance its functionality. Key options include the scarifier for soil preparation‚ aerator for improving soil airflow‚ and edger for precise bordering. Additionally‚ narrow tines and cultivator attachments are available for specialized tasks. These accessories expand the tiller’s versatility‚ allowing users to tackle multiple gardening and landscaping projects efficiently. Each attachment is designed to integrate seamlessly with the Mantis Rototiller‚ ensuring optimal performance and ease of use. This range of options makes the Mantis Rototiller a versatile tool for diverse yard care needs.

6.2 Installing and Using the Scarifier Attachment

Installing the scarifier attachment on your Mantis Rototiller enhances soil preparation by removing dead grass and debris. Begin by removing the tines and securing the scarifier in place. Adjust the depth setting based on your soil conditions. When in use‚ maintain steady control and overlap passes slightly for even coverage. The scarifier is ideal for lawn renovation and improving drainage. Always wear protective gear and ensure the area is clear of obstacles. This attachment simplifies tough tasks‚ making it a valuable addition to your gardening toolkit.

6.3 Aerator and Edger Attachments

The Mantis Rototiller supports aerator and edger attachments‚ expanding its versatility. The aerator attachment improves soil drainage and root growth by creating small holes‚ while the edger helps create clean borders. Installation typically involves securing the attachment to the tiller’s frame. For the aerator‚ adjust the depth setting and overlap passes slightly for consistent coverage. The edger is ideal for maintaining straight lines and can be used on various surfaces. Both attachments enhance your gardening tasks‚ making soil preparation and lawn maintenance more efficient. Always follow safety guidelines and ensure proper alignment for optimal results.

Safety Guidelines and Precautions

Always wear protective gear‚ ensure the area is clear of debris‚ and follow manual instructions. Be aware of your surroundings and keep children and pets away. Regularly inspect the tiller for damage and ensure all guards are in place. Proper safety practices prevent accidents and ensure safe operation.

7.1 General Safety Tips for Operators

Always wear protective gear‚ including gloves‚ safety glasses‚ and sturdy footwear. Ensure the area is clear of debris and bystanders. Operate the tiller on level ground and avoid overreaching. Keep loose clothing tied back and long hair secured. Never leave the tiller unattended while running. Be mindful of uneven terrain and obstacles. Follow all instructions in the manual and ensure proper training before use. Regularly inspect the machine for damage or wear. Maintain a firm grip on the handles and stay alert to prevent accidents.

7.2 Protective Gear and Clothing

Always wear safety glasses or goggles to protect your eyes from debris. Use sturdy gloves to maintain grip and prevent blisters. Closed-toe‚ slip-resistant footwear is essential to avoid foot injuries. Wear long pants and long-sleeved shirts to shield skin from cuts or abrasions. A dust mask is recommended when tilling dry soil to avoid inhaling dust. Consider ear protection‚ as the tiller can emit loud noises. Ensure loose clothing is tied back and long hair is secured to prevent entanglement with moving parts. Proper attire enhances safety and comfort while operating the Mantis Rototiller.

7.3 Operating in Different Terrain and Conditions

Adjust your tilling technique based on soil type and moisture. Soft soil requires less force‚ while hard ground may need slower‚ deeper passes. On slopes‚ maintain stability by tilling across the incline‚ not up or down. Avoid tilling wet soil to prevent clogging the tines. In rocky or debris-filled areas‚ proceed cautiously to avoid damage. For uneven terrain‚ make multiple shallow passes to ensure even tilling. Always reduce speed in challenging conditions to maintain control and safety. Consult the manual for specific adjustments recommended for varying terrain and weather conditions.

Warranty and Customer Support

Your Mantis Rototiller is backed by a comprehensive warranty. Refer to the manual for details on coverage and duration. Contact customer support for assistance or parts inquiries. Online resources and community forums also provide additional troubleshooting and maintenance guidance to ensure optimal performance and longevity of your product.

8.1 Understanding the Warranty Coverage

Your Mantis Rototiller is backed by a comprehensive warranty provided by Schiller Grounds Care‚ Inc; The warranty covers defects in materials and workmanship for a specified period. It is essential to read and understand the terms to ensure your product remains under warranty. The manual details the duration of coverage‚ what is included‚ and any conditions that may void the warranty. Proper maintenance and adherence to guidelines are crucial for maximizing warranty benefits. Refer to the manual for full details on warranty terms and conditions to enjoy hassle-free service from your Mantis Rototiller.

8.2 Contacting Customer Support

For assistance with your Mantis Rototiller‚ contact Schiller Grounds Care‚ Inc. customer support. Reach them via phone‚ email‚ or through their official website. The manual provides contact details and hours of operation. Whether you need troubleshooting‚ parts inquiries‚ or warranty assistance‚ their team is available to help. Ensure you have your model number and purchase details ready for efficient service. Visit their website for additional resources‚ FAQs‚ and online support forms. Prompt and professional assistance is just a call or click away to address any concerns with your Mantis Rototiller.

8.3 Online Resources and Community Forums

Explore online resources and community forums for additional support with your Mantis Rototiller. The official Schiller Grounds Care website offers manuals‚ FAQs‚ and troubleshooting guides. Join forums like manualzz or dedicated gardening communities to connect with other users‚ share tips‚ and find solutions. YouTube channels feature repair tutorials and user experiences. These platforms provide valuable insights‚ helping you troubleshoot issues‚ optimize performance‚ and learn from others. Engage with the community to enhance your tilling experience and resolve challenges effectively.

Environmental and Storage Considerations

Proper storage and eco-friendly practices ensure longevity. Store in a dry‚ protected area‚ and winterize by draining fuel. Dispose of waste responsibly‚ following local regulations.

9.1 Eco-Friendly Usage Tips

Adopt eco-friendly practices to minimize environmental impact. Use the correct fuel type to reduce emissions. Regularly maintain the tiller to prevent oil leaks and ensure optimal performance. Store the machine in a dry‚ protected area to avoid rust and contamination. Winterize by draining fuel to prevent spills. Dispose of waste responsibly‚ recycling parts when possible. Follow local regulations for hazardous materials disposal. By adhering to these tips‚ you contribute to sustainability while extending your tiller’s lifespan.

9.2 Proper Storage and Winterization

Properly store your Mantis Rototiller to ensure longevity. Clean the machine thoroughly before storage to prevent dirt buildup. Drain the fuel tank or stabilize the fuel to avoid stale gasoline. Apply a rust inhibitor to metal parts and store in a dry‚ protected area. Winterize by checking for worn or damaged parts and replacing them. Cover the tiller to protect from dust and moisture. Regular maintenance before storage ensures it remains in good condition for the next use.

9.3 Disposal and Recycling Guidelines

When disposing of your Mantis Rototiller‚ follow eco-friendly practices. Check local regulations for hazardous waste disposal‚ as parts like batteries and fuel may require special handling. Recycle metal components by separating them from plastic and other materials. Drain all fluids‚ such as oil and fuel‚ and dispose of them responsibly. Consider donating functional parts to repair shops or charities. Avoid sending the entire unit to landfills if possible. Proper disposal ensures environmental protection and adheres to sustainability practices. Always prioritize recycling to reduce waste and promote responsible resource management.

Advanced Tips for Optimal Performance

Maximize efficiency by adjusting tine depth for soil type. Use attachments like scarifiers for deeper cultivation. Regularly sharpen blades for better soil penetration and cleaner cuts.

10.1 Maximizing Tilling Efficiency

To maximize tilling efficiency‚ ensure the tines are sharp and properly angled. Adjust the tine depth based on soil type and hardness. For hard-packed ground‚ start with shallow passes and gradually increase depth. Use the scarifier attachment for breaking up tough soil. Maintain consistent engine speed to prevent stalling. Clear debris regularly to avoid clogging. Proper tire pressure and balanced weight distribution also enhance performance. Regular maintenance‚ like lubricating moving parts‚ ensures smooth operation and extends the tiller’s lifespan. These practices optimize efficiency and reduce physical effort required during tilling sessions.

10.2 Customizing Your Tiller for Specific Tasks

Customize your Mantis Rototiller by attaching specialized tools like the scarifier for soil preparation or the aerator for improving soil airflow. The edger attachment helps create clean borders‚ while the narrow tine set is ideal for tight spaces. Adjust the tine depth and angle to suit different soil types and tasks. For heavier-duty work‚ consider upgrading to a larger tine set. Experiment with handlebar height and grip positions for better ergonomics. These customizations allow you to tailor the tiller to your garden’s unique needs‚ enhancing both efficiency and versatility for various landscaping projects.

10.3 Upgrading and Modifying Your Tiller

Upgrade your Mantis Rototiller with a high-capacity air filter for improved engine performance or install heavy-duty tines for tougher soil conditions. Consider modifying the handlebar height for better ergonomics or adding a custom paint job for durability. Users have successfully replaced the carburetor with aftermarket parts for enhanced fuel efficiency. Some enthusiasts even rebuild the engine for increased power. Explore online forums for DIY modification ideas‚ such as adding a wheel kit for easier transport. Always consult the manual before making significant changes to ensure compatibility and safety.

Repair and Replacement of Parts

Identify worn parts and replace them promptly to maintain performance. Common replacements include the carburetor‚ diaphragm‚ and tines. Follow manual guidelines for safe repairs.

11.1 Identifying Wear and Tear

Regularly inspect your Mantis Rototiller for signs of wear and tear. Check the tines for dullness or damage‚ and the carburetor for cracks or blockages. The diaphragm in the carburetor is prone to cracking‚ which can disrupt fuel flow. Engine components like piston rings and cylinders may show wear over time‚ leading to reduced performance. Look for excessive vibration‚ unusual noises‚ or decreased tilling efficiency‚ as these can indicate worn parts. Addressing these issues early prevents costly repairs and ensures optimal functionality. Always refer to the manual for specific inspection guidelines and replacement procedures.

11.2 Replacing the Carburetor and Diaphragm

To replace the carburetor and diaphragm on your Mantis Rototiller‚ start by disconnecting the fuel line and removing the air filter. Gently pull the carburetor off the engine. Inspect for cracks or damage‚ especially in the diaphragm‚ which regulates fuel flow. Install a new carburetor assembly‚ ensuring it’s securely attached. Reattach the fuel line and air filter. If the diaphragm is damaged‚ replace it separately by carefully removing the old one and fitting the new part. Proper installation ensures smooth engine operation and prevents fuel leaks. Always consult the manual for specific torque and alignment guidelines.

11.3 Rebuilding the Engine and Transmission

Rebuilding the engine and transmission of your Mantis Rototiller involves disassembling the components‚ inspecting for wear‚ and replacing damaged parts. Start by removing the engine casing and carefully extracting the piston and crankshaft. Inspect the transmission gears and bearings for damage. Replace any worn or corroded parts with genuine Mantis components. Reassemble the engine‚ ensuring proper alignment and torque specifications. Finally‚ test the tiller to ensure smooth operation. This process restores performance and extends the lifespan of your machine‚ preventing future breakdowns and maintaining efficiency.

User Reviews and Feedback

Users praise the Mantis Rototiller for its ease of use and durability. Many highlight its versatility with attachments‚ though some note it can be heavy for small users.

12.1 Common Praise and Positive Experiences

Many users commend the Mantis Rototiller for its ease of use and durability. The lightweight design and powerful engine make it ideal for small to medium-sized gardens. Several owners highlight the versatility of attachments‚ such as the scarifier and aerator‚ which enhance its functionality. The manual’s clear instructions and troubleshooting guide are also praised for simplifying maintenance. Users appreciate how the tiller handles tough soil with minimal effort. Overall‚ the Mantis Rototiller is often described as a reliable and efficient tool for gardening enthusiasts. Its performance and longevity have made it a favorite among many gardeners.

12.2 Common Complaints and Criticisms

Some users report issues with the Mantis Rototiller’s engine‚ particularly difficulty starting after extended storage. Others mention the carburetor diaphragm cracking‚ which disrupts fuel flow. A few users find the assembly process confusing due to unclear instructions. Additionally‚ the tiller’s vibration during operation can be uncomfortable for some. While the machine is praised for its power‚ occasional complaints arise about the durability of plastic components. Despite these issues‚ most users agree that the tiller performs well once properly maintained and assembled. Regular maintenance‚ as outlined in the manual‚ helps mitigate many of these concerns.

12.3 User-Generated Modifications and Hacks

Users have shared creative modifications to enhance their Mantis Rototiller’s performance. Some have added custom handles for better control‚ while others installed aftermarket tines for tougher soil. DIY enthusiasts have also experimented with engine upgrades‚ such as adjusting carburetor settings for improved fuel efficiency. Additionally‚ users have fabricated custom attachments‚ like seed spreaders‚ to expand the tiller’s functionality. These modifications showcase the versatility of the Mantis Rototiller and the resourcefulness of its owners. However‚ it’s important to ensure any changes comply with safety guidelines and warranty terms to avoid potential issues.